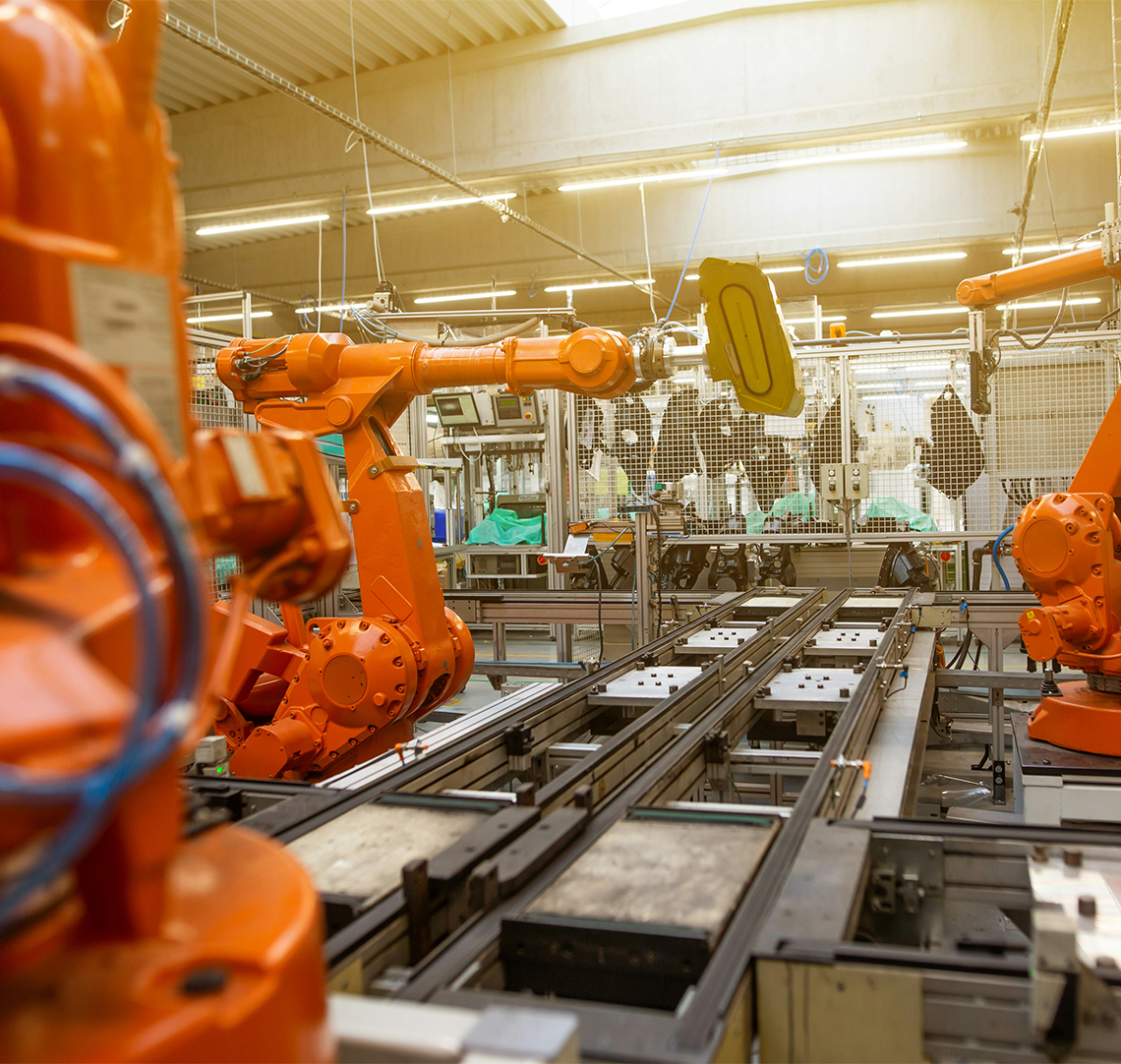

Transforming Manufacturing for a Greener Future

Sustainability practices in manufacturing have shifted from being optional trends to essential components of modern business strategy. Today, consumers, regulators, and stakeholders expect companies to operate responsibly and minimise their environmental impact. Integrating sustainable practices into manufacturing processes is no longer just a choice; it is a necessity. Beyond helping the planet, these practices can lower costs, improve efficiency, and enhance your company’s reputation. This guide explores practical strategies that protect the environment while driving profitability and long-term business success.

For manufacturers looking to showcase their commitment to sustainability online, our Manufacturing Web Design services can create a digital platform that highlights eco-friendly initiatives and innovation.

Energy Efficiency: A Cornerstone of Sustainable Manufacturing

One of the most impactful ways to make manufacturing more sustainable is through energy efficiency. Reducing energy consumption not only lowers carbon emissions but also decreases operational costs over time. Upgrading to modern, energy-efficient machinery can dramatically cut power usage, while optimising production processes through technologies such as programmable logic controllers (PLCs) ensures precision and minimises waste. Incorporating renewable energy sources, such as solar panels or wind turbines, can further reduce reliance on non-renewable power, creating long-term savings and supporting greener operations.

Reducing Waste for a Cleaner Operation

Waste reduction is a critical element of sustainable manufacturing. Lean manufacturing techniques, including value stream mapping and just-in-time production, help cut down on unnecessary materials, making processes more efficient. Recycling and reusing materials such as metals, plastics, and paper further reduce environmental impact. Additionally, choosing eco-friendly packaging that is either recyclable or biodegradable not only demonstrates environmental responsibility but also resonates with customers who increasingly prioritise sustainability in the brands they support.

Choosing Sustainable Materials

The choice of raw materials significantly affects a manufacturer’s sustainability performance. Using recycled resources reduces demand for virgin materials, while renewable alternatives such as bamboo or organic cotton offer a smaller environmental footprint. Avoiding materials that release harmful chemicals during production or disposal ensures safer workplaces and contributes to environmental protection. By carefully selecting sustainable materials, manufacturers strengthen their green credentials and reinforce their commitment to responsible production.

Effective Water Management

Water is a vital resource in manufacturing, and managing it responsibly is essential for sustainability. Implementing water recycling systems allows water to be reused in production processes, significantly lowering overall consumption. Where possible, dry cleaning or low-water-use alternatives should be adopted, and monitoring water usage closely can identify inefficiencies while ensuring regulatory compliance. Effective water management supports environmental stewardship and enhances the resilience of business operations.

Building a Culture of Sustainability

Sustainability in manufacturing is not just about technology, it is about people. Creating a company-wide culture of sustainability is crucial for lasting impact. Employee training ensures that staff understand the importance of sustainable practices and how they benefit the business and the environment. Engagement initiatives encourage employees to contribute ideas and participate in green projects, while setting clear, measurable sustainability targets allows for progress tracking and accountability. When sustainability becomes embedded in everyday decision-making, it transforms the entire organisation.

A Greener Future in Manufacturing

Implementing sustainability practices in manufacturing delivers benefits for both the environment and the business. By focusing on energy efficiency, waste reduction, sustainable materials, and responsible water management, companies can improve operational performance and reduce their environmental footprint. Embedding these practices into your core strategy positions your business as a leader in sustainable manufacturing, prepared for a resilient, eco-conscious future.